Inline Inspection Services

What is Inline Inspection?

Inline inspection is essential for assessing the internal conditions of pipelines and plays a crucial role in pipeline integrity and maintenance programs. The process involves inspection points along the production line, ensuring products meet quality standards using specific gauges for each task.

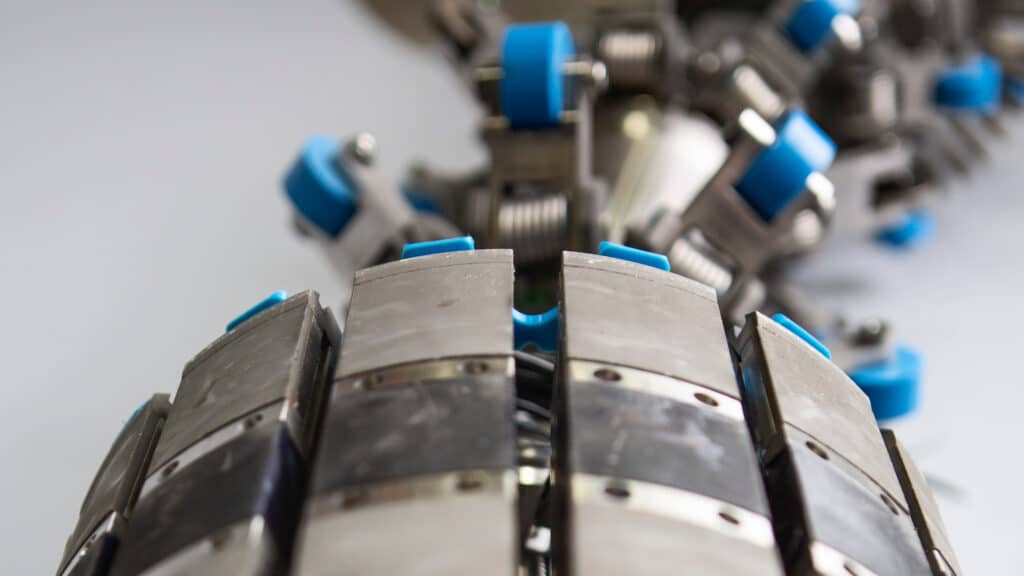

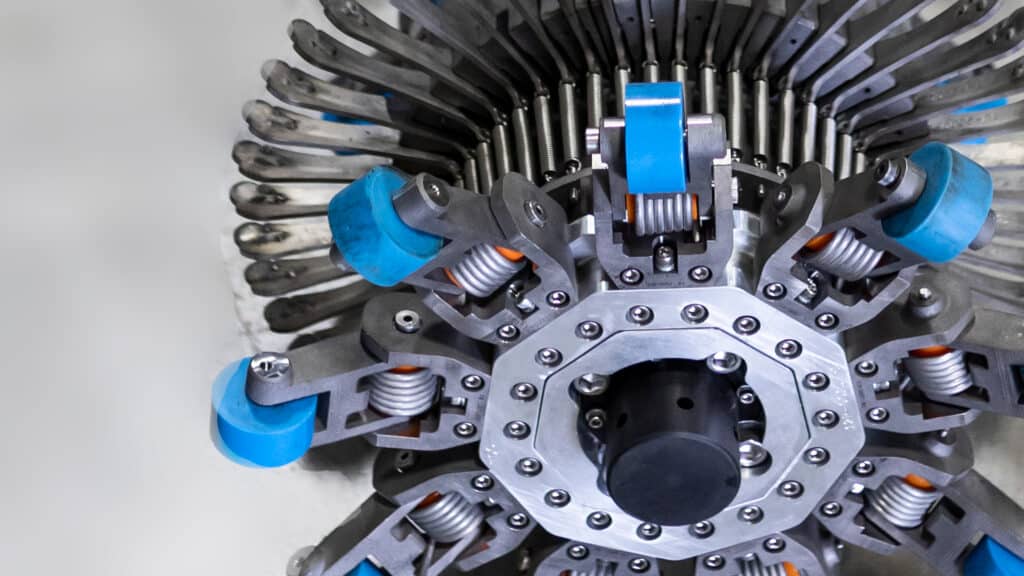

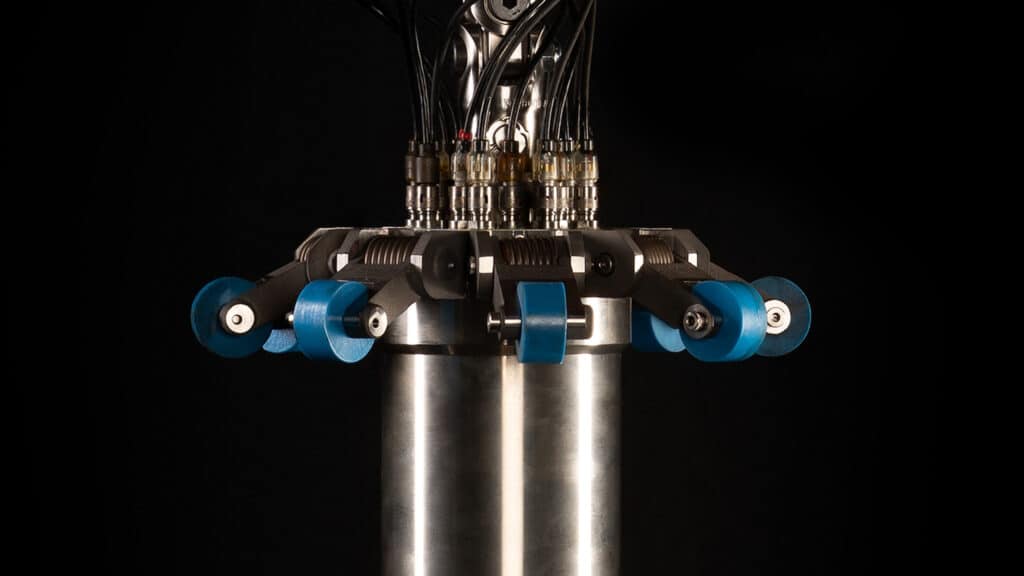

A key tool in inline inspection is the Pipeline Inspection Gauge (PIG), often referred to as a “smart pig.” These devices are equipped with advanced sensors that detect anomalies like corrosion, cracks, dents, and other mechanical defects.

How does inline inspection work?

Inline inspection devices may contain multiple data collection modalities in a single pig. For example, UPP’s smart pigs are complex combo tools that can analyze several deficiencies simultaneously.

The key technologies for pipeline inline inspection include:

Full Tri-Axis MFL (Magnetic Flux Leakage): Detects and sizes metal loss anomalies.

CAL (Caliper) Technology: Measures pipeline geometry and detects dents and deformations.

Integrated IMU (Inertial Measurement Unit): Precisely maps pipeline coordinates and identifies alignment changes.

Why do companies conduct inline inspections?

Inline inspection tools enhance safety by detecting issues like cracks, corrosion, or metal loss, which can lead to leaks or pipeline bursts. Early detection allows for timely intervention, preventing environmental damage and protecting human lives. Additionally, proactive maintenance can prevent costly repairs and extend the pipeline’s lifespan.

Have questions about pipeline inline inspection?

Inline inspection services are vital for maintaining pipeline integrity, preventing potential hazards, and ensuring safe and efficient operations. By leveraging advanced technologies and proactive measures, pipeline operators can detect and address issues before they escalate, safeguarding both the environment and public safety.